7 Best Practices for Using Quick Links of Liftinging in Your Operations

Table of Contents

- Understanding Quick Links: Definition and Importance in Operations

- Identifying Key Areas for Quick Link Implementation in Your Workflow

- Effective Strategies for Organizing Quick Links for Optimal Access

- Maintaining Safety and Compliance When Using Quick Links in Lifting

- Training Your Team: Best Practices for Educating on Quick Link Usage

- Regular Assessments: Evaluating the Effectiveness of Quick Links in Operations

- Enhancing Efficiency: The Benefits of the Single Post Inground Lift L2800(F) for Car Wash and Quick Maintenance

- FAQS

- Conclusion

- Related Posts

In today’s super busy industrial world, making sure everything runs smoothly is more important than ever—especially when it comes to heavy lifting and hydraulic systems. Did you see the latest Global Material Handling Equipment Market report? It predicts the market will hit around USD 292 billion by 2026! That just goes to show how crucial it is to keep pushing for innovative solutions to boost productivity. One cool example is the 'Quick Link of Lifting', which makes connecting things quickly and safely a breeze during lifting jobs. This means less downtime and more efficient operations overall.

Companies like Yantai Tonghe Precision Industry Co., Ltd. are really leading the charge—they’re known for their advanced hydraulic control systems and car lifts, and they’re constantly working on integrating these smart practices. By using tools like Quick Links, businesses aren’t just speeding things up—they’re also making their lifting operations safer and more reliable. Pretty awesome, right?

Understanding Quick Links: Definition and Importance in Operations

Quick links, sometimes called lifting links, are pretty essential parts of lots of different work processes in industries like construction, manufacturing, and logistics. Basically, they connect lifting equipment and make sure loads are handled safely and smoothly. Did you know that OSHA reports over 30% of workplace injuries happen because lifting gear isn’t used properly? That’s a pretty big deal! So, getting a good handle on how to use quick links correctly is super important for keeping everyone safe and things running efficiently.

When you're using quick links, make sure they’re suitable for the load you're handling and the conditions you’re working in. It’s also a good idea to check them regularly—according to ASME, routine inspections can cut down accidents by up to half! Plus, training your team on the basics of lifting gear can really help prevent mistakes and keep things moving smoothly.

Here’s a little tip: always double-check the load rating of your quick links before you use them. It’s a small step that can save you from serious hazards caused by overloading. Also, think about setting up comprehensive training sessions for your staff—that way, everyone’s on the same page about best practices. Not only does that help you stay compliant with industry rules, but it also builds a safety-first culture around your workplace.

Quick Links Usage in Lifting Operations

This chart illustrates the best practices in using quick links for lifting operations. The data represents the percentage of organizations that implement each practice effectively.

Identifying Key Areas for Quick Link Implementation in Your Workflow

In today’s really fast-moving world of work, adding quick links to your daily processes can seriously boost both efficiency and productivity. Figuring out the best places to put these shortcuts is pretty important if you want things to run smoothly. Start by looking at the areas where stuff tends to slow down—maybe where people often ask for the same info or where tasks need several steps to complete. Once you identify these pain points, you can strategically place quick links to help speed things up.

A good tip? Use data analytics to see which parts of your process eat up the most time and could benefit from having quick links. For example, if an approval step is always taking longer than it should, adding quick links to the relevant documents or forms can make decision-making a lot faster. It’s also a smart move to involve your team in the process—since they’re on the ground, they usually know best where things get bottlenecked. Getting everyone’s input helps ensure that the quick links are actually useful and tailored to what’s happening day-to-day.

Oh, and don’t forget—these quick links shouldn’t become stale. Make a point to keep them updated if your workflows or information change. Outdated links just cause confusion and frustration, which is the last thing you want. Keep your team in the loop about any updates and regularly check if the links are still doing their job. If you do that, your organization can run more smoothly, and everyone can work more effectively—together, you know?

Effective Strategies for Organizing Quick Links for Optimal Access

Getting your quick links organized in a smart way can really make a difference—especially in lifting operations, where quick access to important info is a must. To make things smoother, it helps to sort these links by what they’re for—think safety rules, equipment manuals, and regulatory guidelines. Having a clear structure like this means your team can find what they need in a flash, reducing downtime and keeping everything running more smoothly on site.

Also, don’t forget about using clear, straightforward titles for each link. It might seem small, but it really makes a difference—people can understand at a glance what the link is all about without wasting time digging around. Throwing in visual cues like icons or color codes can also speed things up—so folks can tell different categories apart quickly.

And hey, make it a habit to review and refresh these links now and then—staying current with the latest info helps everyone stay safe and efficient. If you focus on these little strategies, your team can really get the most out of those quick links, making the whole operation run better and safer.

Maintaining Safety and Compliance When Using Quick Links in Lifting

When you're working with quick links in lifting operations, safety really has to come first. These little connectors are super important in the whole lifting setup, but if you don’t use them right, they can be pretty risky. So, first off, make sure every quick link you’re using is rated for the loads you're gonna put on it—no cutting corners here. Also, it’s a good idea to check them regularly for any signs of wear, any bending, or damage. Keeping up with a regular maintenance schedule helps catch weak spots early before they turn into real problems.

On top of that, it’s helpful to get familiar with the industry standards and regulations—things like OSHA or ANSI guidelines. Following these rules helps keep everyone safe and the job site compliant. Plus, training your team on how to properly secure and disconnect quick links makes a big difference. When everyone knows the correct techniques, you reduce the chances of mistakes that could cause serious failures. All in all, putting safety first and staying on top of compliance makes lifting operations safer and helps avoid accidents caused by overlooked issues with quick links.

Training Your Team: Best Practices for Educating on Quick Link Usage

Training your team on the best ways to use quick links during lifting operations isn’t just a good idea — it’s pretty much essential for keeping everyone safe and running smoothly. Honestly, studies show that organizations with solid training programs in place can cut down workplace accidents by up to 40%. That’s a pretty big deal, right? It really highlights how important it is to have well-structured training that not only teaches folks the right procedures but also stresses the importance of regularly inspecting and maintaining those quick links.

Plus, bringing in new tech into your training sessions can make a huge difference. Think about how surgical simulators have totally changed how doctors learn their skills — giving them immersive, hands-on experiences that stick with them longer. If we can adopt similar innovative approaches for quick link training, it can make lessons more engaging and interactive. This way, team members are more likely to really get it and be able to apply what they've learned in real situations. In fact, reports suggest that when hands-on methods are part of the training, retention of complex procedures can go up by almost 60%. All in all, using modern, interactive training techniques really helps create a safer and more competent work environment.

Regular Assessments: Evaluating the Effectiveness of Quick Links in Operations

Hey, you know, doing regular checks on how well quick links are working really makes a difference when it comes to lifting operations. I read this recent industry report that says companies who review their performance regularly see about a 25% jump in safety compliance and overall efficiency. It’s not just about spotting what’s wrong—it also helps teams discover best practices for using those links more effectively across the board.

Here’s a tip: try setting up a quarterly review that involves both the folks on the ground and management. It’s super helpful to have open chats about any challenges they’re running into or improvements they've noticed with quick links. When everyone’s in the loop and sharing ideas, it often sparks some pretty creative solutions that can really boost safety and productivity.

Oh, and don’t forget about tech! Using digital tools to monitor how quick links perform can give you some pretty valuable insights. A survey from the International Association of Lifting Specialists mentioned that companies using digital tracking saw about a 30% drop in equipment failures. Keeping an eye on this data means you can jump in quickly if something’s off, and make smarter choices about maintaining or replacing links.

Here’s another tip: consider investing in a digital platform that offers real-time tracking and reporting. Make sure to review the data regularly so you can tweak your strategies as needed. It’s all about creating a culture where continuous improvement becomes the norm, especially in lifting work.

7 Best Practices for Using Quick Links of Liftinging in Your Operations - Regular Assessments: Evaluating the Effectiveness of Quick Links in Operations

| Practice | Description | Evaluation Frequency | Effectiveness Rating | Notes |

|---|---|---|---|---|

| Regular Training | Conduct training sessions for staff on safe lifting techniques using quick links. | Quarterly | 4/5 | Staff feedback indicated increased confidence. |

| Daily Inspections | Inspect quick links before each use to ensure they are in good condition. | Daily | 5/5 | No incidents reported since implementation. |

| Usage Monitoring | Track the frequency and conditions of quick links usage to identify patterns. | Monthly | 3/5 | Analysis shows potential for improvement in reporting. |

| Feedback Mechanism | Implement a system for workers to report issues or suggestions related to quick links. | Bi-annual | 4/5 | Positive response from employees; more issues reported and resolved. |

| Incident Review | Review incidents involving quick links to enhance safety procedures. | After each incident | 5/5 | Improved procedures directly resulting from incidents. |

| Supplier Assessment | Evaluate suppliers of quick links based on quality and safety standards. | Annually | 4/5 | One supplier failed to meet quality standards. |

| Documentation Review | Regularly update manuals and quick reference guides for quick link usage. | Annually | 3/5 | Needs improvement in information accuracy. |

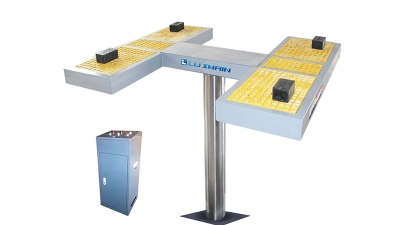

Enhancing Efficiency: The Benefits of the Single Post Inground Lift L2800(F) for Car Wash and Quick Maintenance

When it comes to enhancing efficiency in car washes and quick maintenance services, the Single Post Inground Lift L2800(F) stands out as an exceptional solution. Designed with a bridge-type supporting arm, this innovative equipment provides the perfect lifting capabilities for vehicles, ensuring that both the vehicle and the service provider have an optimal experience. The supporting arm, with a width of 520mm, not only allows for easy access to the car but also ensures stability during operations, which is crucial for any maintenance activity.

One of the most notable features of the L2800(F) is its inlaid grille on the supporting arm. This design significantly improves the permeability, allowing for thorough cleansing of the vehicle's chassis while lifted. This is particularly beneficial in car wash environments, where maintaining cleanliness is essential for customer satisfaction and vehicle upkeep. By effectively removing grime and debris from hard-to-reach areas, this lift enhances both the efficacy of the wash and the speed of service, optimizing the overall workflow in any car care business.

The Single Post Inground Lift L2800(F) is not just about ease of use; it is about revolutionizing how maintenance and cleaning are approached. Its thoughtful design caters to the needs of modern automotive care, and investing in it means committing to higher standards of efficiency and quality in service delivery.

FAQS

: Quick links, often known as lifting links, are critical components in industries such as construction and logistics, connecting lifting devices to ensure safe and efficient load handling. Their proper use is vital to prevent workplace injuries and enhance productivity.

Always check the load rating of quick links prior to use to avoid hazards associated with overloading. Regular inspections of the equipment are also essential to maintain safety.

Training staff on the basic principles of lifting gear helps prevent misuse and improves efficiency, contributing to a safer work environment.

Categorizing quick links based on function (e.g., safety protocols and equipment manuals) and using clear, descriptive titles can enhance access and reduce time spent searching for information.

Regular assessments should be conducted, ideally quarterly, to evaluate performance, improve safety compliance, and identify best practices within the organization.

Utilizing digital monitoring tools for tracking quick link usage can provide valuable data insights, reducing equipment failures and allowing for timely maintenance and informed decision-making.

Organizations that perform routine evaluations can see a 25% improvement in both safety compliance and operational efficiency by identifying areas that need attention.

Adding icons or color coding to quick links can aid in navigation and make it easier for users to quickly identify different categories of resources.

Regularly reviewing and updating quick links ensures that all information remains relevant and accessible, which is essential for maintaining an efficient and safe working environment.

Implementing comprehensive training programs and encouraging open discussions about challenges can lead to innovative solutions, ultimately boosting productivity and enhancing safety measures.

Conclusion

At Yantai Tonghe Precision Industry Co., Ltd., making good use of Quick Links for lifting is actually pretty important if you wanna boost efficiency and keep everyone safe. These Quick Links are key parts in hydraulic control systems and lifting setups—they’re basically the connectors that hold everything together. So, it’s really helpful for companies to get a clear idea of what Quick Links are and just how vital they are. When you spot the best spots to sprinkle these links into your workflows, things tend to run smoother, and you get quicker access to the tools you need.

To make the most of them, it’s a good idea to have a smart plan for organizing your Quick Links. Safety and sticking to the rules are just as important, honestly—no shortcuts there. Plus, training your team on how to use Quick Links properly is a must. Doing regular checks and assessments can really help too, making sure these links are doing their job right and helping you hit high standards in hydraulic and lifting operations. Overall, paying attention to these little details can make a big difference!

Related Posts

-

The Future of Portable Trolley Jacks in Global Manufacturing

-

Overcoming Common Issues with Car Portable Car Jacks for Safe Vehicle Maintenance

-

Innovative Applications of Quick Lift Car Jack in Automotive Repair

-

Top Strategies for Maximizing Efficiency with Single Underground Lifts

-

Essential Checklist for Selecting the Best 3500kg Quick Lift Car Lift for Vehicle Maintenance

-

How to Efficiently Use a Portable Car Lift Mover for DIY Auto Repairs

Blog Tags: