Innovative Strategies for Quick Link of Liftinging Applications

Table of Contents

- Innovative Digital Solutions in Lifting Applications

- Top Technologies Shaping the Future of Lifting Operations

- Enhancing Efficiency with Real-Time Data Integration

- Best Practices for Implementing Digital Solutions in Lifting

- Exploring the Role of AI in Lifting Application Optimization

- Key Metrics for Evaluating Lifting Application Performance

- Transform Your Garage: The Ultimate Guide to Using a Portable Car Quick Lift Motorcycle Lift Kit

- FAQS

- Conclusion

- Related Posts

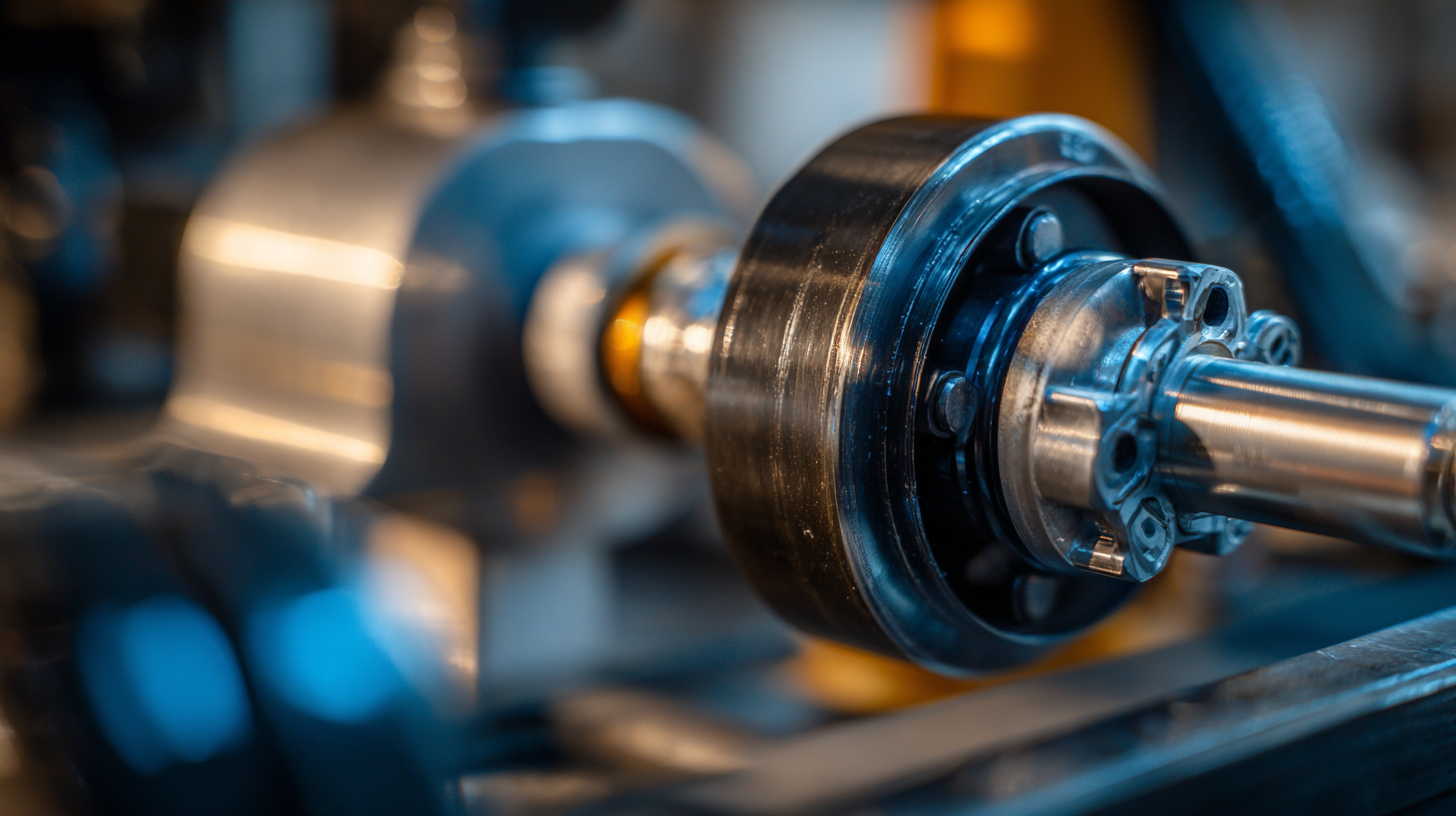

In today’s fast-changing industrial world, finding efficient and innovative solutions for lifting stuff is more important than ever. Yantai Tonghe Precision Industry Co., Ltd. is really stepping up in this space, focusing on developing and making hydraulic control systems, cylinders, and car lifts. A recent market report from Industry Research actually shows that the global market for hydraulic lifts is expected to grow quite a lot, thanks to advances in automation and the rising demand for smarter lifting options. One cool trend they’re seeing is something called the “Quick Link of Lifting,” which makes operations smoother and safer across a bunch of industries—think construction, auto, and more.

As we dive into these new strategies and tech, I think you'll see how our innovative approaches can really change the game in lifting applications, leading to a more productive and efficient future.

Innovative Digital Solutions in Lifting Applications

When it comes to lifting applications these days, you can’t ignore how innovative digital tools are shaking things up. Not only do they boost efficiency — saving time and effort — but they also make safety and compliance way easier to manage.

I recently read a report from Allied Market Research that predicts the global lifting equipment market will hit around $50.5 billion by 2027. A big part of this growth? It’s driven by the rising use of cutting-edge tech like IoT and AI. These smart tools are totally transforming the game, letting companies monitor everything in real-time and catch problems early with predictive maintenance. That means less downtime and lower operational costs overall — pretty impressive, right?

But, to really get the most out of these digital solutions, there are a few best practices worth keeping in mind. For starters, regular training sessions for operators are a must — helps everyone stay up-to-date and confident with the latest tech. Plus, using cloud-based platforms can make a huge difference, allowing teams to communicate smoothly and get quick insights into the lifting operations. It’s all about working smarter, not harder.

Oh, and don’t overlook telematics — integrating it into your lifting gear is super important for tracking how equipment performs and staying on top of safety regs. Industry data shows that companies using telematics can see up to a 25% boost in equipment utilization. All in all, jumping on these digital innovations can seriously level up efficiency and set the stage for some exciting growth down the line.

Top Technologies Shaping the Future of Lifting Operations

You know, the way lifting operations are evolving is pretty fascinating these days. Thanks to all the new tech coming into play, things are getting faster, safer, and overall way more efficient. More companies are jumping on the bandwagon with cool robotics and AI tools to make logistics and lifting tasks smoother. For example, you’ve got these advanced robots, packed with sensors, that are totally transforming workplaces — handling the boring, repetitive, and physically tough jobs so that workers can focus on more complex stuff. It’s a win-win because it keeps everyone safe and helps get more done in less time.

As industries push further into automation, having smarter lifting tech really becomes a game changer. These innovative solutions can actually give real-time data and analytics, so operators can make smarter decisions right on the spot. And they’re pretty versatile, fitting right into everything from warehouses to construction sites. All these recent innovations show a real commitment to improving efficiency and sustainability, and honestly, it’s clear that modern tech is going to be a huge part of how lifting operations look in the future.

Enhancing Efficiency with Real-Time Data Integration

In today's world, where real-time data is more important than ever, lifting applications really boost their efficiency when they tap into new strategies. By syncing live data with lifting operations, companies can get better at managing loads and making quicker decisions. This kind of integration means operators get immediate feedback, so they can tweak settings on the fly—making things safer and more productive all at once.

To make this work well, it’s smart to invest in IoT gadgets that keep you updated about equipment health and load conditions in real time. Plus, using advanced analytics can help spot patterns early, so you can head off problems before they even happen. It’s also super helpful to keep communication flowing smoothly between devices and the folks on the ground, maybe through mobile apps—that way, everyone’s got instant access to the info they need.

And let’s not forget—training your team on how to read and respond to live data is key. Regular workshops and even simulation drills can turn your crew into quick, confident decision-makers. Building a culture that values data-driven choices will lead to smoother lifting operations and, in the end, better overall performance.

Best Practices for Implementing Digital Solutions in Lifting

In today's really fast-paced industrial world, using digital solutions for lifting tasks has become pretty much essential if you want to boost efficiency and keep things safe. The first thing you should do is really get a good understanding of what your needs are. It’s a good idea to look at your current systems, figure out what’s missing, and see where digital tools could make a difference. Plus, bringing in folks from different departments to weigh in helps ensure you’re choosing the right tech—that actually fits your specific needs.

And, let’s not forget about training and support—these are super important for things to really click. It’s key to run thorough training sessions so everyone gets comfortable with the new digital tools. Ongoing support is just as crucial because it keeps the transition smooth and helps employees feel more confident using the new tech. Also, making a habit of reviewing and updating your digital solutions regularly can really help keep things running smoothly and nip any problems in the bud. If you focus on these practices, you'll end up with a much more streamlined, effective lifting process that can boost productivity and safety all around.

Innovative Strategies for Quick Link of Lifting Applications

This chart illustrates the best practices for implementing digital solutions in lifting applications based on various key dimensions including Efficiency, Cost Reduction, Safety Improvement, and User Adoption. The data represents the improvements observed following the adoption of digital solutions.

Exploring the Role of AI in Lifting Application Optimization

The lifting applications scene is going through some pretty big changes lately, mainly thanks to all the advancements in artificial intelligence—yeah, AI is really shaking things up. I read a recent report from MarketsandMarkets that says the AI stuff in construction could hit around 2.5 billion dollars by 2026, growing at an impressive rate of about 34.8% annually. It’s not just about working faster; AI is also making everything safer on jobsites, so it’s become pretty much a must-have in today’s construction world.

By bringing AI into lifting operations, companies can cut down on downtime and save a good chunk of change. For example, predictive analytics can catch potential equipment problems before they happen, helping teams stay ahead of breakdowns with proactive maintenance. This kind of approach can slash operational hiccups by as much as 20%. If you’re running a crew, it’s a smart move to start using AI tools to analyze data on the fly—this way, you're making smarter decisions and handling loads more efficiently.

Tip: Make sure your team gets regular training on these new AI tools. It keeps everyone in sync and helps you get the most out of the tech.

And here’s another cool thing—AI-powered drones are becoming game-changers, especially for site inspections and monitoring. These drones, packed with AI, can check out site conditions, giving you real-time info on things like wind speed and other environmental factors. According to a report by Grand View Research, use of drones in construction is expected to go beyond 30% by 2025.

Tip: Think about setting up a solid data management system to handle all the info coming from these AI tools. That way, you can respond faster and keep your projects on track without hassle.

Key Metrics for Evaluating Lifting Application Performance

In today's fast-changing world of lifting applications, keeping an eye on key performance metrics is pretty much essential if you want to really optimize operations. Metrics like predicting oil flow in gas lift systems are becoming even more important, especially now that machine learning is playing a bigger role. These predictive models can help us make sense of all the complexities in oil production—basically, they show us how different factors interact and impact output. By using the latest algorithms, companies can tweak their strategies to boost production, even in tricky well environments.

And don’t forget about brand lift metrics—they’re super important when it comes to performance marketing. Things like awareness, consideration, and intent give us a clear picture of how our campaigns are doing. Focusing on the real impact of marketing efforts helps companies fine-tune their approach and get the most bang for their buck. When it comes to gas lift allocation, some pretty innovative methods are emerging, like leveraging IoT tech and hybrid optimization algorithms. These tools are making it possible to make smarter, data-driven decisions that really can level up the efficiency of lifting operations.

Transform Your Garage: The Ultimate Guide to Using a Portable Car Quick Lift Motorcycle Lift Kit

Transforming your garage into a functional workspace becomes seamless with the right tools. One essential addition to your setup is a portable car quick lift motorcycle lift kit. The LM-1 Motorcycle Lift kit stands out for its high-quality construction, being welded from 6061-T6 aluminum alloy, known for its excellent strength-to-weight ratio. This enables mechanics and enthusiasts to lift motorcycles effortlessly while ensuring durability for repeated use.

Beyond construction materials, the LM-1 features an integrated set of wheel holding devices that enhance stability, making it safer during maintenance tasks. By simply bringing the left and right lifting frames together, bolting them, and locking the assembly onto the quick lift, users can create a secure lifting system. According to industry reports, the demand for home garage lifts has surged, with market analysts predicting a growth rate of over 5% annually as hobbyists and professionals alike recognize the advantages of at-home maintenance and repair solutions.

Investing in a reliable lift kit not only improves efficiency but also encourages proper maintenance, which is critical for prolonging the life of your motorcycle. Adopting such tools in your garage aligns with the growing trend where 60% of motorcycle owners prioritize DIY repairs, particularly for seasonal preparations. By incorporating the LM-1 Motorcycle Lift kit into your garage, you empower yourself to tackle maintenance with confidence and precision.

FAQS

: Advanced technologies such as robotics and AI solutions are significantly enhancing the efficiency, safety, and overall performance of lifting operations.

Robots equipped with sophisticated sensors perform repetitive and physically demanding tasks, protecting workers from injury and allowing them to focus on more complex responsibilities, which boosts productivity.

Real-time data analytics enables operators to make informed decisions on the go, enhancing operational efficiency and catering to the specific needs of various sectors.

Companies should conduct a thorough needs assessment, involve stakeholders, provide comprehensive training, and ensure ongoing support for successful digital integration.

AI enhances lifting operations by reducing downtime and operational costs through predictive analytics, which can foresee potential equipment failures and allow for proactive maintenance strategies.

AI-powered drones can inspect and monitor site conditions, providing real-time data on factors like wind speeds, which significantly streamlines lifting operations.

The AI in the construction market is expected to reach $2.5 billion by 2026, growing at a compound annual growth rate (CAGR) of 34.8%.

Implementing a robust data management system helps handle the influx of insights from AI tools, optimizing response times and keeping projects on track.

Comprehensive training sessions help employees familiarize themselves with new tools, boosting their confidence and enhancing the effectiveness of the technology usage.

Periodic reviews and updates of digital solutions can help optimize performance and promptly address any emerging issues.

Conclusion

In the fast-changing world of lifting applications, new digital tools are really shaking things up, making operations smoother and more efficient. One of the coolest advancements right now is the use of real-time data — it’s like having instant feedback, so operators can make smarter decisions on the fly and keep everything running seamlessly. Companies like Yantai Tonghe Precision Industry Co., Ltd. are leading the charge with their hydraulic control systems that support what they call a 'Quick Link of Lifting.' If you ask me, focusing on best practices when rolling out these digital solutions can make a huge difference in safety and overall performance during lifting jobs.

And here’s another exciting part: AI technology is starting to play a major role in optimizing lifting processes. By digging into important metrics, companies can see how well their systems are working and spot areas where they can do better. As more industry players jump on board with these innovative tech trends, the future of lifting looks pretty bright — more efficient, safer, and full of new possibilities.

Related Posts

-

Unlocking Efficiency: The Advantages of Quick Lift Floor Jacks in Automotive Maintenance

-

Comparing the Benefits of Portable Column Lift vs Traditional Lift Systems

-

Innovative Applications of Quick Lift Car Jack in Automotive Repair

-

Transforming Your Workflow in 2025 with the Best Mobile Lift Solutions for Global Buyers

-

Ultimate Checklist for Sourcing the Best Car Scissor Lift Portable for Your Business Needs

-

The Ultimate Guide to Choosing the Right Portable Crane Lift for Your Needs

Blog Tags: