Top Strategies for Maximizing Efficiency with Single Underground Lifts

Table of Contents

- Identifying Common Challenges with Single Underground Lifts

- Key Factors Affecting the Efficiency of Underground Lifts

- Best Practices for Preventing Operational Issues

- Innovative Solutions to Enhance Lift Performance

- Periodic Maintenance: A Strategy for Longevity and Efficiency

- Enhancing Safety and Efficiency: A Comprehensive Review of the L2800(F-1) Hydraulic Inground Lift

- FAQS

- Related Posts

In today’s world, where space is tight and getting things done quickly is more important than ever, Single Underground Lifts are really making a difference across different industries. You’ve probably noticed in busy city spots—where every square foot counts—these lifts are changing the game. According to the latest report on the Global Hydraulic Lifts Market, demand for smart, innovative lifting solutions is expected to grow about 5.5% each year. That’s mainly thanks to advances in hydraulic control tech that make these systems even better. Yantai Tonghe Precision Industry Co., Ltd. is leading the charge here, focusing on designing and making hydraulic control systems, cylinders, and lifts that businesses can rely on. By adopting these modern technologies, companies can boost their efficiency and make workflows smoother. In this blog, I’ll share some top strategies for integrating these cool underground lifts into your operations—so you can stay ahead of the curve and work smarter, not harder.

Identifying Common Challenges with Single Underground Lifts

When it comes to using single underground lifts in city infrastructure projects, spotting the common hurdles is pretty important if you wanna keep things running smoothly. A recent review points out that while new digital tech can really improve how we build and maintain underground systems, we’re still dealing with some issues—like how we handle data integration and keep tabs on things in real-time. For example, many underground projects run into delays because of not doing enough upfront planning, which can lead to surprises down the line. In fact, nearly 30% of these installations face setbacks for exactly this reason, highlighting just how crucial better planning is.

And let’s not forget safety. Poor management and maintenance of these lifts can cause all sorts of problems, both efficiency-wise and safety-wise. In fact, about a quarter of the reported issues in construction involve lift-related incidents, which really stresses the importance of sticking to strict safety rules and doing regular checks. Luckily, by using the latest digital tools and getting the prep work right from the start, we can tackle these challenges head-on. That way, we can improve underground lift operations and make everything safer and more reliable for everyone involved.

Key Factors Affecting the Efficiency of Underground Lifts

When you're dealing with underground lifts, there are actually quite a few things that really impact how well they work. I read a report from the International Association of Elevator Engineers, and it mentioned that the energy these lifts use can vary a lot depending on how they’re designed and run. For example, newer lifts with regenerative drives can cut down on energy use by as much as 30%. That’s pretty cool, right? It’s a win for sustainability, and it also helps keep things running smoothly.

Another biggie is how well you take care of the lifts. Regular check-ups and smart maintenance plans can make a huge difference — studies show they can operate about 20% more efficiently than lifts that aren’t maintained as often. Putting a solid maintenance routine in place not only reduces the chances of unexpected breakdowns but also helps the equipment last longer. Plus, things like managing how much weight you put in and how fast the lift moves can really boost efficiency too. Some research even suggests that when load is properly distributed, you can speed things up without overloading the system. All these little details just go to show that planning ahead is key if you wanna get the most out of underground lifts.

Top Strategies for Maximizing Efficiency with Single Underground Lifts

Best Practices for Preventing Operational Issues

When you're running a single underground lift, it’s super important to keep everything running smoothly and safely. Fixing small issues before they become big problems can save you a lot of headaches down the line. That’s why regular maintenance checks should be part of your routine. Check the mechanical parts, hydraulic systems, and electrical wiring — basically, give everything a once-over to catch anything weird early on. If you deal with small hiccups right away, you’ll avoid costly downtime and keep the lift performing at its best.

Also, a big part of making everything run safe and efficient is making sure everyone involved knows what they’re doing. Proper training is key — everyone should be comfortable with the lift’s controls, safety features, and emergency procedures. And don’t forget, keeping up with ongoing education about the best ways to operate the lift and spotting common issues can make a huge difference.

Lastly, communication really is king. Make sure there’s a clear way for team members to report any oddities or concerns without hesitation. Creating an environment where folks feel comfortable speaking up helps prevent misunderstandings and possible accidents. Encouraging open dialogue about what’s going on with the lift means problems get caught early, safety gets a boost, and everything runs more smoothly. Follow these simple tips, and you’ll see fewer operational troubles and a more efficient lift operation overall.

Innovative Solutions to Enhance Lift Performance

In today’s busy world of construction and maintenance, getting the most out of those underground lifts is super important. Luckily, there are some cool new solutions that can really boost lift performance — things like cutting-edge tech and more efficient workflows. For example, a recent report from the American Society of Civil Engineers mentioned that fine-tuning lift systems could cut down on downtime by up to 25%. That means projects get done on time more often, which is a big win, right?

One of the best ways to improve how these lifts work is by adding IoT sensors and smart monitoring tech. A study from the International Lift Equipment Association showed that using real-time data analytics can actually predict issues before they happen — so maintenance can be done proactively. That leads to fewer unexpected repairs, sometimes as much as 30% fewer! Plus, upgrading to high-efficiency hydraulic systems can boost lift speeds by over 20%, helping everything move faster on-site.

And let’s not forget about making lifts more user-friendly and safer. Implementing ergonomic designs and advanced safety features doesn’t just make operators’ lives easier; it can also cut workplace accidents by around 15%, according to the National Safety Council. Focusing on these innovative ideas—like smarter tech and safer, more comfy lifts—can really make a big difference, making construction safer, more efficient, and more sustainable overall.

Periodic Maintenance: A Strategy for Longevity and Efficiency

Keeping up with regular maintenance is really key if you want your underground lifts to run smoothly and last longer. I was reading a report from the International Organization for Standardization (ISO) the other day, and it mentioned that doing routine check-ups can boost your lift’s efficiency by up to 30%. Honestly, it’s not just about safety (though that’s super important) — it also helps you avoid those dreaded expensive breakdowns that can shut things down unexpectedly. Setting up a regular maintenance schedule means you can catch problems before they become big issues, keeping everything running at its best.

If you’re serious about making your underground lifts last and perform well, here are a few tips. First off, create a solid maintenance plan that includes regular inspections, lubrication, and testing to make sure everything’s working as it should. According to the American National Standards Institute (ANSI), businesses that stick to scheduled maintenance end up saving about 25% on repair costs — not too shabby! Next, invest in good quality spare parts and keep your components up-to-date so they meet the latest industry standards. And don’t forget, training your team on proper use and maintenance is a game-changer. Studies show that around 70% of equipment failures are actually caused by operator error. So, by sticking to regular maintenance and these tips, you’ll see your lifts working more efficiently and lasting longer than ever before.

Enhancing Safety and Efficiency: A Comprehensive Review of the L2800(F-1) Hydraulic Inground Lift

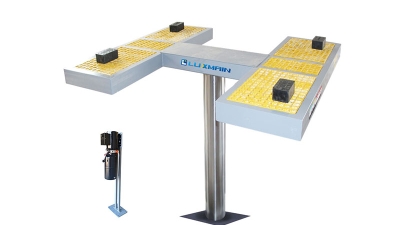

The L2800(F-1) Hydraulic Inground Lift offers a cutting-edge solution for enhancing safety and efficiency in automotive servicing. With its innovative bridge-type supporting arm, this hydraulic lift ensures optimal accessibility during maintenance tasks. The inlaid grille within the supporting arm not only maximizes structural integrity but also provides excellent permeability, allowing for thorough cleaning of the vehicle's chassis. This feature is particularly vital, as research indicates that regular chassis cleaning can significantly extend the lifespan of a vehicle's undercarriage components and improve overall performance.

In addition to its advanced design, the L2800(F-1) lift excels in space efficiency. When not in use, the lifting posts can retract smoothly into the ground, rendering the support arm flush with the floor. This space-saving functionality is crucial in small repair shops and beauty salons, where floor real estate is at a premium. According to a report by the Automotive Lift Institute, such integration of lifts with minimal footprint has led to a 25% increase in operational efficiency for busy service centers, proving that high-tech solutions can coexist with practical work environments.

Moreover, the versatility of the L2800(F-1) makes it an ideal choice for various repair tasks. Whether it's minor mechanical repairs or detailing work, this hydraulic inground lift adapts seamlessly to the demands of the job, ensuring that service providers can conduct operations safely and effectively. Emphasizing both safety and efficiency, the L2800(F-1) stands as a testament to modern automotive service technology.

FAQS

: Key factors include lift design, operational conditions, maintenance regimen, load management, and operational speed.

Regenerative drives can reduce energy consumption by up to 30%, promoting sustainability and optimizing performance.

Regular maintenance can lead to lifts operating up to 20% more efficiently, minimize downtime, and prolong the lifespan of the equipment.

A maintenance regimen should include routine inspections of mechanical components, hydraulic systems, and electrical wiring to identify potential issues early.

Thorough training ensures all operators understand lift controls, safety features, and emergency protocols, which contributes to safety and operational efficiency.

Clear communication helps prevent misunderstandings and ensures that any anomalies or concerns are reported promptly, enhancing safety and performance.

Proper load distribution can enhance lift speed without overextending the system’s capacities, thereby improving overall efficiency.

Operational speed that is well-managed in conjunction with load can significantly impact the efficiency and performance of underground lifts.

Best practices include regular maintenance checks, thorough training of personnel, and establishing clear communication protocols among team members.

A comprehensive maintenance program minimizes downtime, enhances operational efficiency, and ensures ongoing safe operation of the lifts.

Related Posts

-

Innovative Solutions for Maximizing Efficiency with the Best 6000 Lb Car Lift

-

Unwavering Quality in Chinese Manufacturing: Discover the Best 110v Portable Car Lift

-

How to Choose the Best Portable Hydraulic Jacks for Electric Cars by 2025 Industry Trends

-

Essential Checklist for Selecting the Best 3500kg Quick Lift Car Lift for Vehicle Maintenance

-

Experience Excellence in Manufacturing with the Best Mobile Forklift from a World Class Chinese Factory

-

Transforming Your Workflow in 2025 with the Best Mobile Lift Solutions for Global Buyers

Blog Tags: